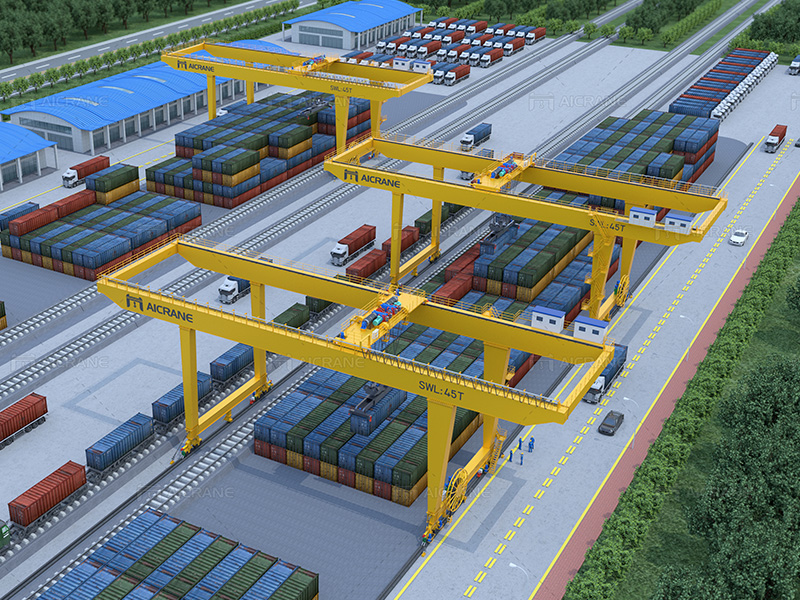

Rail Mounted Gantry (RMG) cranes are essential components in various industries, especially in ports, rail yards, and container terminals. Their ability to lift and transport heavy loads with precision and efficiency makes them invaluable assets for handling bulk cargo and containers. However, investing in an RMG crane requires careful consideration of several factors to ensure optimal performance, safety, and return on investment. This article outlines the key aspects to consider when investing in a rail mounted gantry crane.

1. Assessing Your Operational Needs

Load Capacity and Dimensions

Understanding the specific requirements of your operations is crucial. The load capacity of the RMG crane should match the weight of the heaviest loads it will handle. Overloading a crane can lead to mechanical failure and safety hazards. Additionally, consider the dimensions of the loads to ensure the crane’s span and lifting height are adequate for your needs.

Frequency of Use

Evaluate how frequently the crane will be used. For high-frequency operations, investing in a more robust and durable crane is advisable. Continuous or heavy use can lead to faster wear and tear, necessitating a crane built to withstand such conditions.

Operational Environment

The operational environment plays a significant role in selecting the appropriate RMG crane. Factors such as weather conditions, temperature extremes, and exposure to corrosive elements should be considered. Cranes operating in harsh environments may require special coatings or materials to resist corrosion and wear.

2. Technical Specifications

Span and Lifting Height

The span of the RMG crane, which is the distance between the rails, should be compatible with the layout of your facility. The lifting height should also be sufficient to handle the tallest loads. Ensure that the container gantry crane can reach the necessary height without compromising stability and safety.

Speed and Efficiency

The speed at which the crane can lift and move loads affects overall operational efficiency. Consider both the hoisting speed (vertical movement) and the traveling speed (horizontal movement). A crane with adjustable speed settings can provide flexibility for different tasks, enhancing productivity.

Power Supply

RMG cranes can be powered by various energy sources, including electricity, diesel, or hybrid systems. Electric-powered cranes are generally more environmentally friendly and cost-effective in the long run. However, diesel-powered cranes may be preferred in areas where electric infrastructure is limited. Evaluate the availability and cost of power sources in your location to make an informed decision.

3. Safety Features

Anti-Sway Mechanisms

Anti-sway mechanisms are essential for maintaining load stability during lifting and movement. These systems reduce the sway of the load, enhancing safety and precision. Investing in a crane with advanced anti-sway technology can prevent accidents and damage to both the crane and the cargo.

Overload Protection

Overload protection systems are crucial for preventing the crane from lifting loads beyond its rated capacity. These systems automatically halt operations if an overload is detected, protecting the crane from damage and ensuring the safety of operators and nearby personnel.

Emergency Stop Functions

Emergency stop functions allow operators to quickly halt crane operations in case of an emergency. Ensure that the crane is equipped with easily accessible emergency stop buttons and that operators are trained in their use.

4. Automation and Control Systems

Remote Control

Remote control systems enable operators to control the crane from a safe distance, enhancing safety and flexibility. Modern RMG cranes often come with advanced remote control options, including wireless systems that allow for precise control even in challenging environments.

Automated Operations

Automation can significantly improve the efficiency and accuracy of crane operations. Automated RMG cranes can perform repetitive tasks with minimal human intervention, reducing labor costs and the risk of human error. However, the initial investment in automation technology can be high, so consider the long-term benefits and potential return on investment.

5. Maintenance and After-Sales Service

Regular Maintenance

Regular maintenance is essential for ensuring the longevity and reliability of the RMG crane. Establish a maintenance schedule that includes inspections, lubrication, and replacement of worn parts. Partner with a supplier that offers comprehensive maintenance services and support.

After-Sales Service

The availability of after-sales service is a critical factor in choosing a gantry crane supplier. Ensure that the supplier provides reliable technical support, spare parts, and repair services. A strong after-sales service network can minimize downtime and keep your operations running smoothly.

6. Cost Considerations

Initial Investment

The initial cost of purchasing an RMG crane can be substantial. However, it is important to consider the total cost of ownership, which includes installation, maintenance, and operational costs. Investing in a high-quality crane may have a higher upfront cost but can save money in the long run through reduced maintenance and increased efficiency.

Financing Options

Explore financing options such as leasing, loans, or installment plans. Some suppliers offer flexible financing solutions that can help manage the initial investment and spread the cost over time. Evaluate the terms and conditions of financing options to find the best fit for your financial situation.

7. Regulatory Compliance

Safety Standards

Ensure that the RMG crane complies with local and international safety standards. Compliance with standards such as ISO, OSHA, and CE certification guarantees that the crane meets rigorous safety and performance criteria. Non-compliance can result in legal issues and operational disruptions.

Environmental Regulations

Consider the environmental impact of the crane and ensure compliance with environmental regulations. Electric-powered cranes are generally more environmentally friendly, reducing emissions and energy consumption. Evaluate the crane’s energy efficiency and potential for minimizing environmental impact.

8. Supplier Reputation

Track Record

Research the reputation and track record of potential suppliers. Look for suppliers with a proven history of delivering high-quality cranes and excellent customer service. Customer reviews, testimonials, and case studies can provide valuable insights into the supplier’s reliability and performance.

Customization Options

Some suppliers like Aicrane machine offer customization options to tailor the RMG crane to your specific needs. Customization can include adjustments to load capacity, span, lifting height, and control systems. Working with a supplier that offers customization can ensure that the crane meets your exact requirements.

Conclusion

Investing in a rail mounted gantry crane is a significant decision that requires careful consideration of various factors. By assessing your operational needs, evaluating technical specifications, prioritizing safety features, and considering maintenance and after-sales service, you can make an informed choice that maximizes the value and efficiency of your investment. Additionally, considering cost factors, regulatory compliance, and the reputation of suppliers will ensure that you select a reliable and high-performing RMG crane that meets your long-term operational goals.