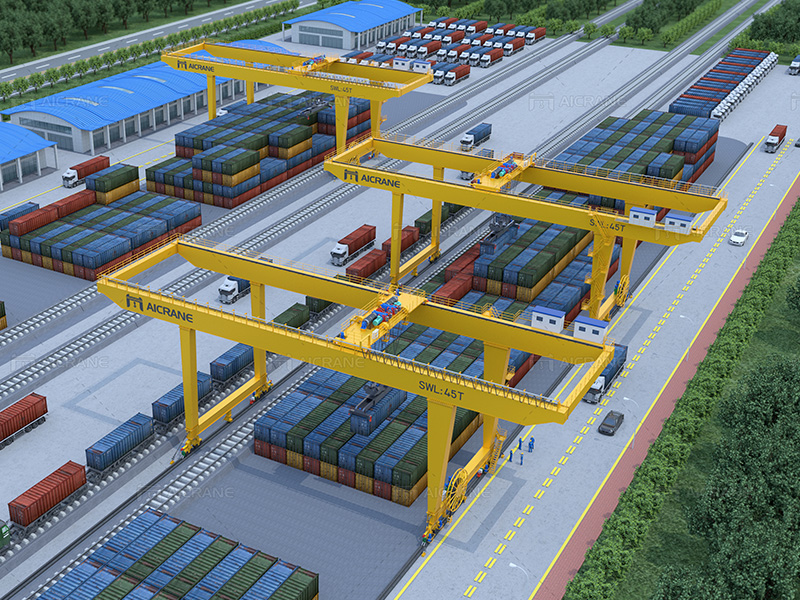

A double girder gantry crane with cantilever is an essential piece of equipment for lifting and moving heavy loads in industries such as construction, shipbuilding, and material handling. It offers increased load capacity and greater stability compared to single girder cranes, particularly when equipped with a cantilever, which extends beyond the crane’s supporting structure, allowing it to cover a larger area.

However, installing a double girder gantry crane with cantilever in hot weather presents unique challenges. Extreme temperatures can affect both the installation crew and the equipment, increasing the risk of accidents and reducing efficiency. This guide covers essential steps and tips for ensuring a safe and successful installation in hot conditions.

Step 1: Pre-Installation Preparation

Before installing the double girder gantry crane with cantilever, proper preparation is key, especially in hot weather. Consider the following:

Site Assessment: Conduct a thorough evaluation of the installation site. Ensure that the ground is stable and level to support the heavy crane structure. In hot weather, the ground might expand or crack, especially on dry soil, so ensure the foundation is secure.

Safety Precautions: Provide adequate sun protection for the workers, such as shaded areas and cooling systems. The crew should wear appropriate personal protective equipment (PPE) to guard against sunburn, dehydration, and heat exhaustion. Additionally, provide enough water for hydration and schedule frequent breaks in cool areas.

Material Checks: Inspect all crane components before installation. Heat can cause certain materials to expand or deform, especially metal parts, which are common in double girder gantry cranes. Ensure all materials meet quality and safety standards and have not been compromised by the high temperature.

Step 2: Assembling the Crane Structure

The assembly of a double girder gantry crane with cantilever requires attention to detail and careful coordination. Here’s how to approach it:

Frame Assembly: Begin by assembling the main frame of the gantry crane, which consists of two girders supported by legs. In hot weather, steel can expand, so it’s crucial to measure tolerances carefully to ensure the frame aligns correctly.

Cantilever Installation: The cantilever must be installed with precision to ensure it extends properly beyond the crane’s main body. This process involves mounting additional components on either side of the gantry crane, allowing the crane to lift and move loads beyond its track system. Use mechanical lifting tools to secure the cantilever arms in place without compromising safety. Verify the cantilever’s stability by checking for correct alignment and load-bearing capacity.

Step 3: Hoisting Mechanism Installation

The hoisting mechanism is responsible for lifting heavy loads, and installing it in hot weather requires specific attention:

Heat-Resistant Lubricants: Ensure that all moving parts, including gears and pulleys, are lubricated with heat-resistant lubricants to avoid breakdowns. Hot weather can cause traditional lubricants to break down or evaporate, leading to mechanical failure.

Wire Rope Installation: Install the wire ropes for the hoist carefully, ensuring they are tensioned correctly. Excess heat can affect wire ropes, potentially causing them to stretch or weaken. Use high-quality, heat-resistant wire ropes to mitigate this issue.

Load Testing: After assembling the hoisting mechanism, conduct load tests to verify that the double girder gantry crane with cantilever https://aicranemachine.com/gantry-crane/cantilever/ can lift the required loads safely. This step ensures that the crane’s hoisting mechanism works correctly even under extreme temperatures.

Step 4: Electrical and Control Systems

The control systems of the double girder gantry crane are essential for its operation, and these systems must be protected against overheating:

Cooling Systems: Install adequate cooling systems for the crane’s motors and electrical components. Overheating can cause electrical failures, leading to operational downtime or accidents. In hot weather, ensure that all electrical systems have proper ventilation or air conditioning units to maintain optimal performance.

Heat-Resistant Cabling: Use heat-resistant electrical cables to prevent insulation from melting or degrading. Proper cable management will ensure that the crane remains operational in extreme weather conditions.

Step 5: Ensuring Worker Safety

Worker safety is always a priority during installation, especially in hot weather:

Hydration and Rest: As temperatures rise, workers are more susceptible to heat-related illnesses such as heatstroke. Provide plenty of water and enforce regular rest periods to prevent fatigue. Implement a work-rest schedule to ensure that employees are not overworked in the heat.

Sun Protection: Equip workers with appropriate sun protection gear, such as wide-brimmed hats and sunglasses. Apply sunscreen frequently and encourage the use of UV-protective clothing.

Temperature Monitoring: Monitor the temperature throughout the installation process. If the heat becomes too extreme, it may be necessary to pause installation during the hottest parts of the day and resume during cooler hours, such as early morning or late afternoon.

Step 6: Testing and Final Adjustments

Once the double girder gantry crane with cantilever has been installed, conduct a series of tests to ensure that it is functioning correctly:

Load Testing: Test the crane with various loads to verify its capacity and ensure the cantilever can handle the specified weight. This is crucial in hot weather as the crane may behave differently under temperature-induced stress.

Movement Testing: Ensure that the crane can move smoothly along its tracks and that the cantilever operates without obstruction. Check for any signs of overheating in the motors or control systems.

Final Adjustments: Make any necessary adjustments to the crane’s alignment, tension, or load-bearing capacity to optimize its performance.

Installing a double girder gantry crane with cantilever in hot weather requires careful planning, attention to detail, and consideration of the environmental conditions. From pre-installation preparation to final load testing, each step must account for the challenges posed by high temperatures. By using heat-resistant materials, ensuring worker safety, and conducting thorough testing, you can install the crane safely and efficiently, even in extreme heat. Whether in construction, shipping, or heavy industry, a well-installed double girder gantry crane with cantilever will provide reliable, long-lasting performance. Get your double girde cantilever gantry crane from Aicrane.