Concrete batching plant popularly known as batching plant is basically equipment that makes concrete by mixing various components. These are highly useful as they do the job very quickly. There are even machines that produce enough concrete to build a huge building in a day.

At the basic level, there are two kinds of concrete batching machines ( maquina de concreto movil ). One that produces a dry mixture and others that produce wet mixture at the end. There are a number of ingredients that are used to make the mixture starting from cement, water, rocks, sand etc.

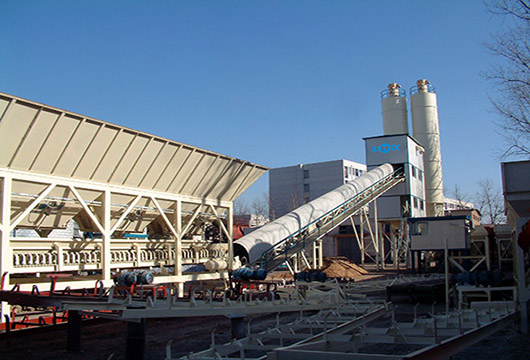

Depending on these, machines are different types, for instance, the one that has the core mixing equipment at the centre of the machine with the ingredient required stored in huge containers around it.

The dry mix plants usually weight all the ingredients and mix them to form a dry mix batch. Then this batch is let in the trucks and then water is added, even water is weighed and added. When it comes to the wet mixer the batch comes out with water mixed in it. Most of the times digital methods are used to weight the ingredients, sometimes manual are also used.

The dry mix is transported to the site of construction by transported which start mixing the water with the mix through the travel time. Mostly 60-100 revolutions are taken to make an even mix. With a wet mix, the difference is the end concrete batch is transported by adding more water so it doesn’t get set while transporting.

Now as said before, the core of the equipment is the mixer ( camion mixer en venta ). This is the thing that makes the concrete batches. This is usually in many types such a dry wit is a tilt at an angle, this is the most popular one. We even see it at the construction site of residential homes. Apart from this, there are many others such as the single shaft, twin shaft. When a large batch of concrete is needed then mostly tilt mixer is used. But if the construction demands even mixing of ingredients then twin-shaft mixers are used. These use motors when making sure that the mixer is evenly made, the and stone are even across the concrete batch made.

In Asia I have seen most tilt drum is mostly used and even in North America, this is the one on the top. Tilt drum is dominating all over as this can make huge amounts at a time, easy to use and there are vehicles that are equipped with tilt drum mixers tags can be used at the site. As this feature enables us to go to the option of wet. The batch which can be made and used then and there. But tilt from mixer doesn’t have its domination in other parts of the world. This position is taken by twin shaft mixer which is used the most in Europe.

When it comes to aggregate bins there are usually compartments. These compartments have the ingredients that are needed to make the batch of concrete. Many times the compartments allocated for cement are more than the ones allocated for any other ingredients (ingredientes). Suppose if there is one each for sand, rock there would be two for cement at least. Conveyors are used to transporting this ingredient to the centre mixer.

We are seeing that tilt drum mixer is preferred by builders in construction sites as it is very easy to use and as well as transport. Plus it doesn’t come with the extra weight of the compartment. We see most of the construction sites be it small, medium, large scale constructions one tilt drum mixer is definitely used. Huge batches are made to catch the schedules of construction.

You might have even seen some tilt drum concrete plants at construction sites, these are the mobile batching plants. These are the top preference these days. Just weight and add the Ingredients and the mix are ready with stone and evenly distributed throughout the batch.

So if you are someone looking to buy a mobile concrete batch maker we suggest you go for The tilt drum mixer. You just have to know about the weights of each ingredient to be put inside it. It rotates the ingredients and after 60-80 rotations the mix is ready to use. Rotations are taken up to 100 for much better mix.

— www.aimixgrupo.com/planta-de-concreto-premezclado-en-venta/